Gate Valves vs. Globe Valves: What's the Difference? Which one is better?

Two common types of valves often used when controlling the flow of liquids or gases in piping systems are gate valves and globe valves. Although the use of the two are similar, are acting to cut off the role of the medium, but there are critical differences between the two types of valves, making them suitable for different piping systems, now let's learn about the differences between gate and globe valves, advantages and disadvantages, and which one is better.

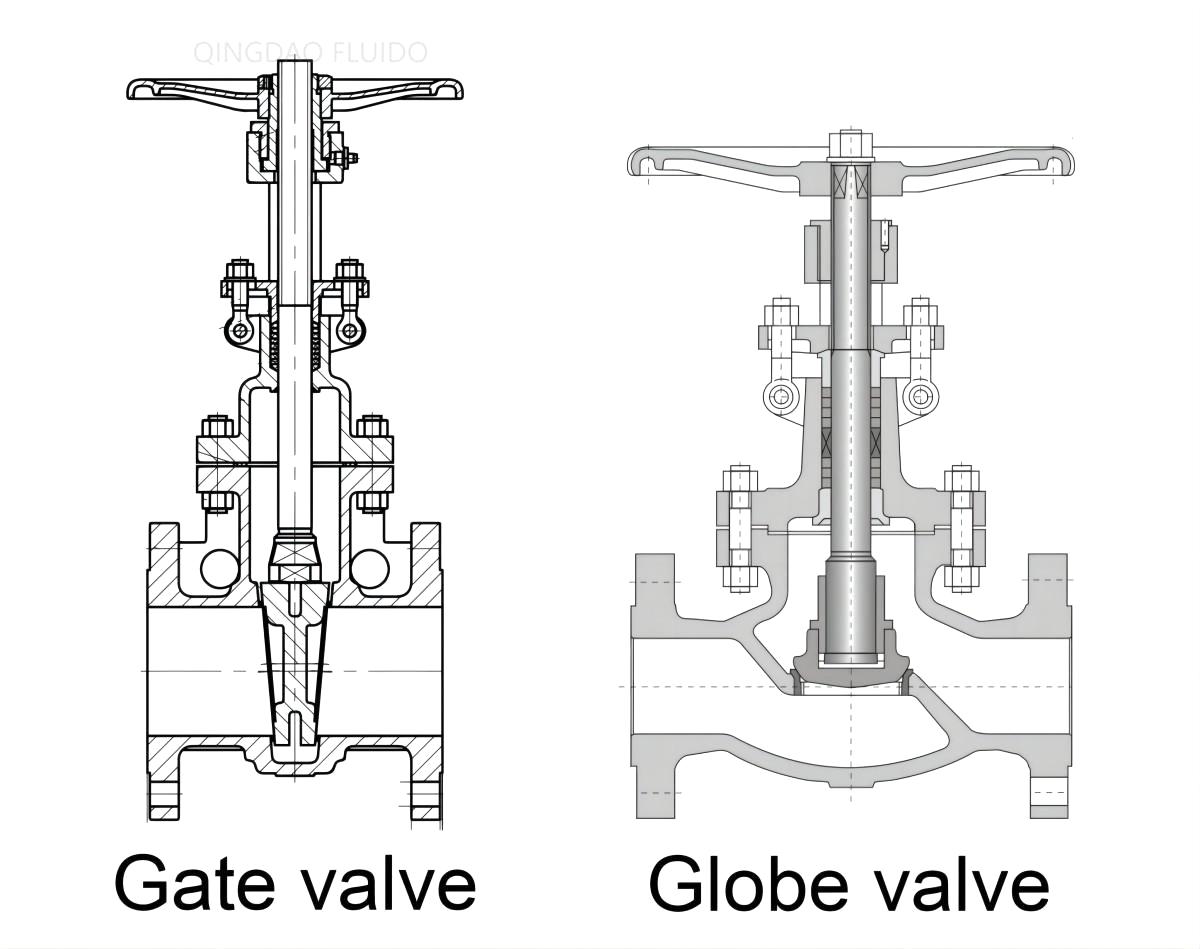

1. The two types of valves have different structures, gate valves are usually larger in size than globe valves because their design consists of plates that move up and down in the valve body. Globe valves, on the other hand, have a more compact design with plate components that are perpendicular to the direction of fluid flow. The gate valve is more complex in structure than the globe valve, and larger in size than the gate valve.

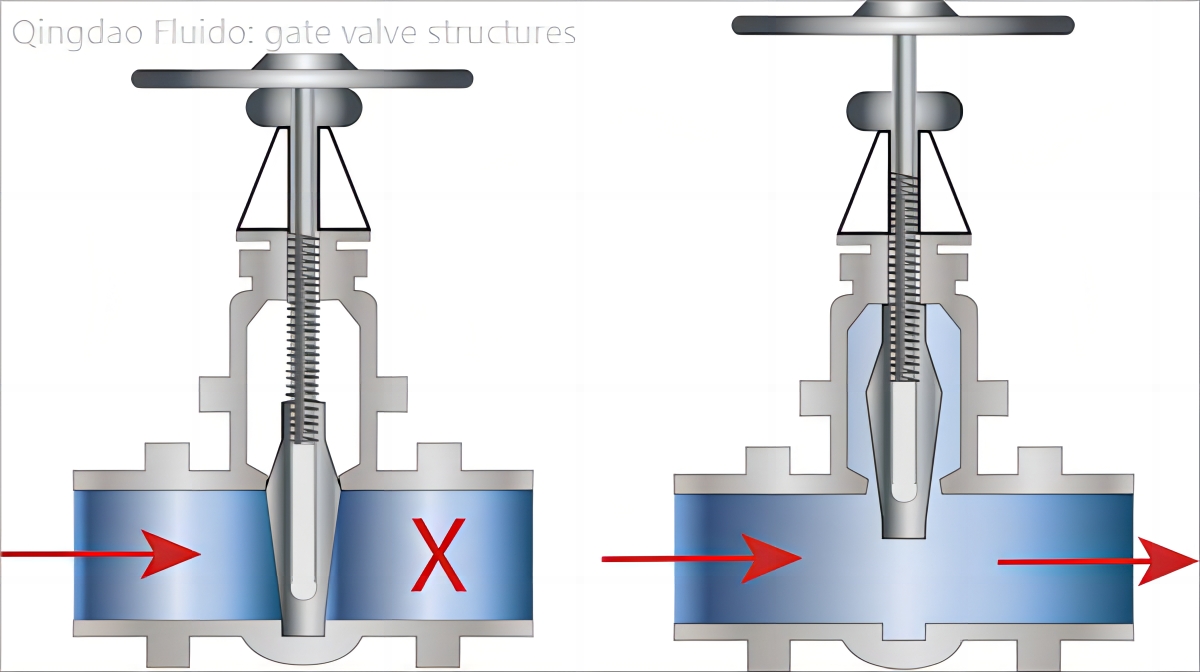

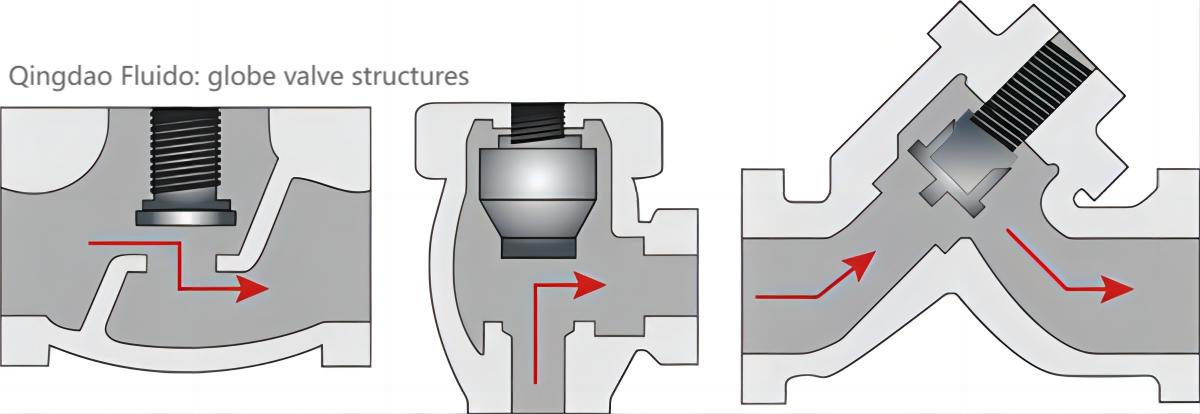

2. When the valve is fully open, the valve plate of the gate valve will not act as an obstruction, the medium can pass through the entire flow path with little pressure loss. Gate valves are usually used for infrequent opening and keep the valve plate completely open or closed working environment. The flow resistance coefficient of the globe valve is greater, the driving force or torque required is also correspondingly much larger, but it can also act as a regulating and throttling of the role of the fluid.

3. Gate valve ends are identical, no need to separate the front and back in the installation. The globe valve is not the same at both ends, in the installation of the medium can enter from below or above the stem. Medium from below the stem into the advantages of the valve is closed when the packing is not pressurized, you can extend the service life of the packing, the valve before the pipeline pressure can be replaced when the packing, generally only applies to DN50 the following small size of the globe valve. Globe valve media from the lower stem into the disadvantage of the valve driving torque is greater, about 1.05-1.08 times the driving torque from the upper part of the entry. The axial force on the valve stem is large, and the valve stem is easy to bend. Therefore, the size of the DN200 above the globe valve are used in the way the medium flows from above.

4. The sealing surface of the gate valve has a certain self-sealing ability, its spool through the deformation of the rubber valve plate and the valve seat sealing surface in close contact. And the sealing surface of the globe valve can only contact each other when completely closed, so the sealing surface of the wear is very small. Globe valve sealing surface wear as long as the spool and the sealing surface of the presence of debris caused by, or due to improper operation, when closing the valve by the medium of high-speed scouring caused.

Valve selection:

Globe valves are simpler in structure than gate valves and have better sealing performance, but the disadvantage is that the fluid resistance is large, and the torque required to open and close is greater, so in pipeline design globe valves are usually only used in small-size pipelines.

Gate valves have less fluid resistance, lower manufacturing costs and easier maintenance. In steam systems and large size pipelines, gate valves are more suitable due to low fluid resistance.

In conclusion, although both gate and globe valves are used to control the fluid flow in pipeline systems, they are suitable for different pipelines because of their respective advantages and disadvantages. Knowing the differences between gate and globe valves can help you choose the correct valve for your pipelines. If you have any questions about gate and globe valves, or would like to get a quick quote on valves, please contact QINGDAO FLUIDO and we will give you the most professional response.