Products

Lug Type Double Offset Butterfly Valve- Resilient Seated

Product Description

Product Details

Introduction

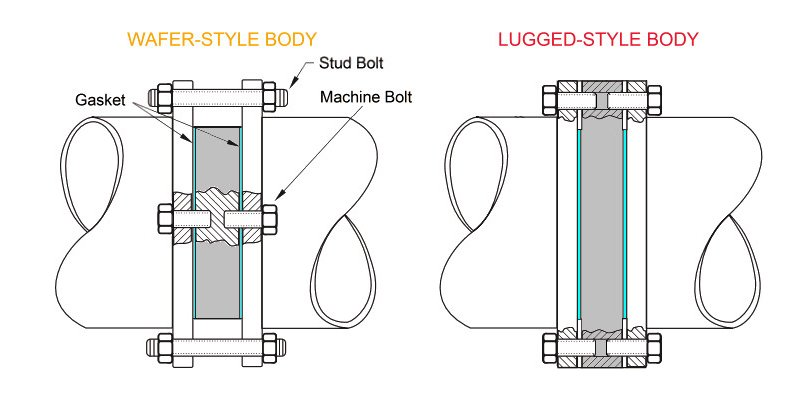

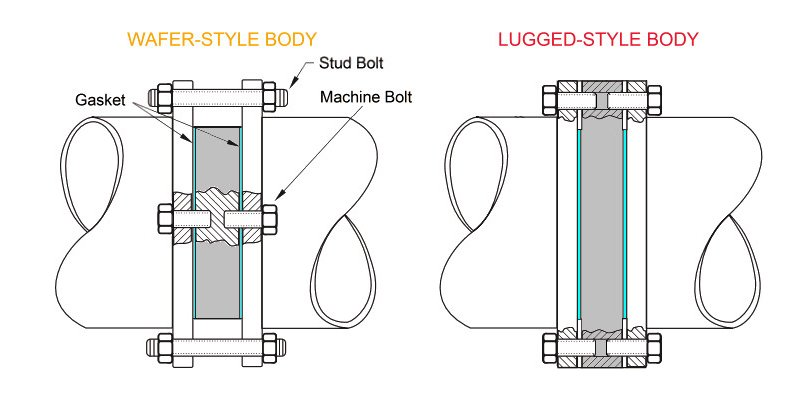

Lug type has its own tapped holes (female threaded) which allow the bolts to be threaded into it from both sides. Unlike other kinds of valve connections, this kind of end connection allows the dismantling of any side of the piping system while keeping the service on the other side. This is the biggest advantage of the butterfly lug-type valve.

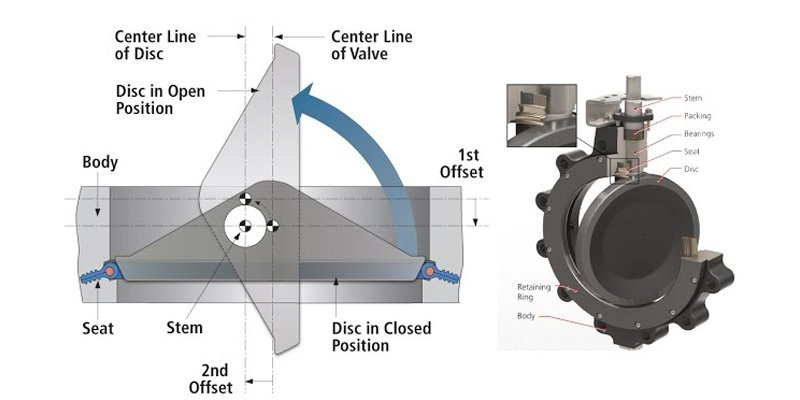

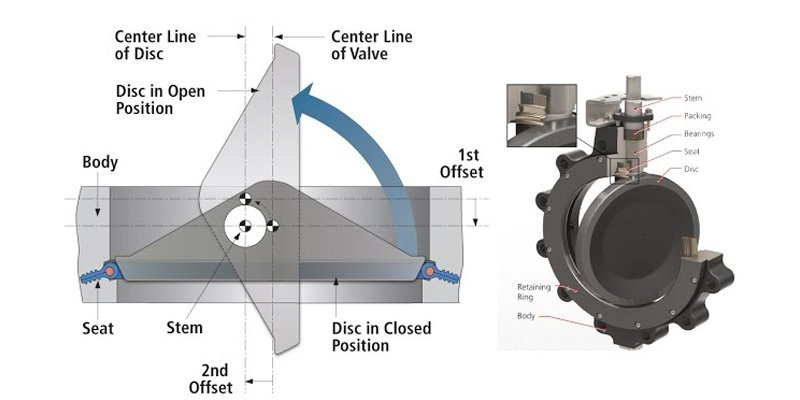

Besides, the double eccentric structure design makes the lug-type butterfly valve a high-performance butterfly valve: the spindle offsets the center of the seal face to form the first eccentric, and the spindle offsets from the centerline of the pipeline to form the second eccentric. The eccentric lug butterfly valve will generate cam effect as the disc screw in or out, making it possible to separate the disc from seat by very small torque. In this way, there’s almost no friction between the disc and seat during switches and the service life is extended.

Specifications

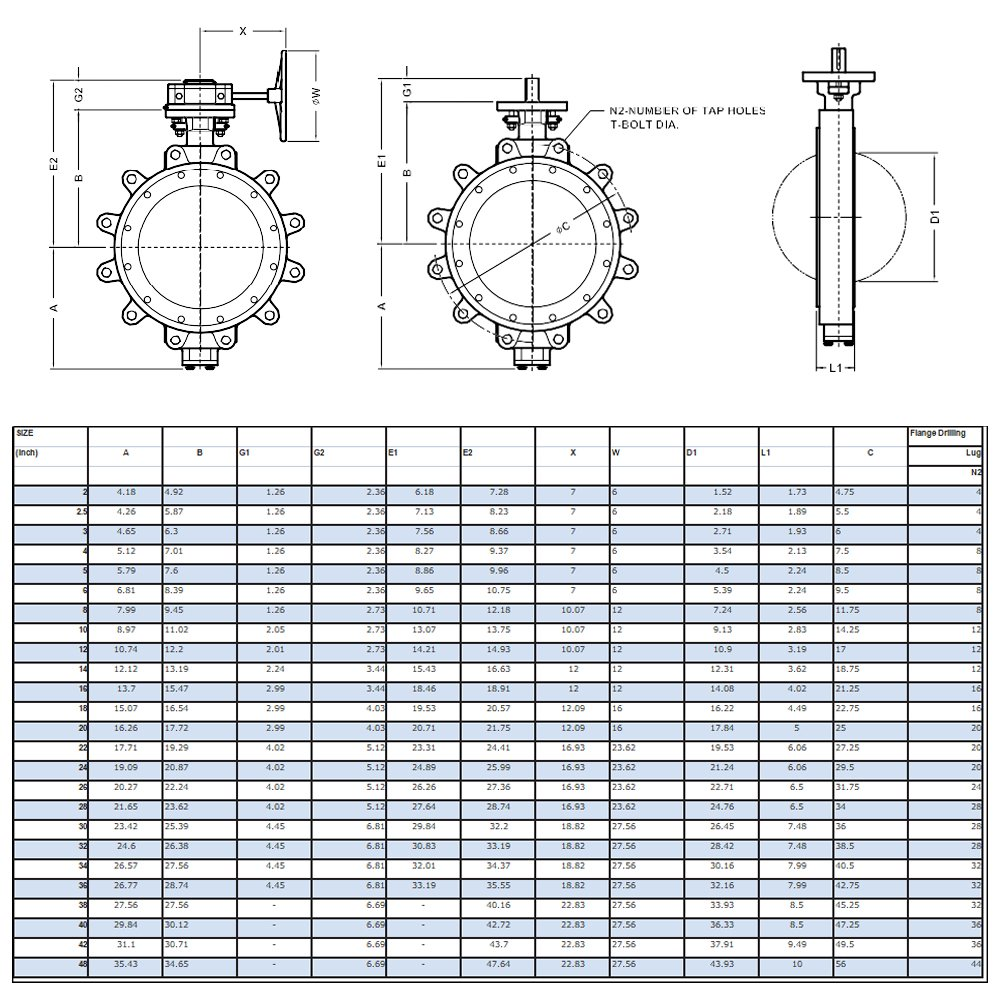

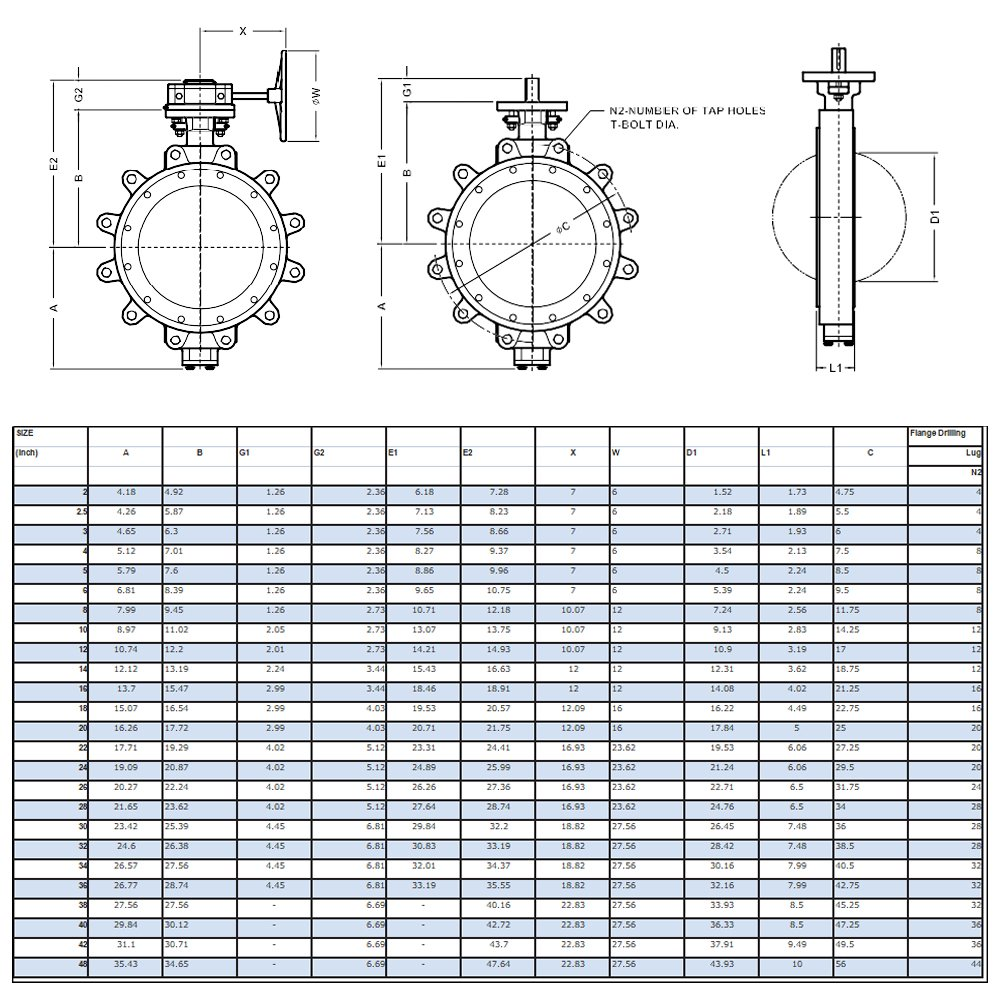

We provide eccentric lug butterfly valves in a wide range of sizes. The main products are the following:

We also offer other sizes according to your demand.

Applications:

As we mentioned before, the lug-type butterfly valve is characterized by a unique connection design allowing the installation or removal of any side of the piping system without the need to shut down the entire system. For this reason, the butterfly lug type valve can even be used where the valve is at the end of a pipe.

Besides, the double offset design contributes to a better sealing effect of the eccentric lug butterfly valve. For this reason, this lug type butterfly valve is used for the applications:

Cooling water, air, gases, fire protection, etc.

Slurry and similar services

Vacuum service

High-pressure and high-temperature water and steam services

Compressed Air or Gas Applications.

Lug type has its own tapped holes (female threaded) which allow the bolts to be threaded into it from both sides. Unlike other kinds of valve connections, this kind of end connection allows the dismantling of any side of the piping system while keeping the service on the other side. This is the biggest advantage of the butterfly lug-type valve.

Besides, the double eccentric structure design makes the lug-type butterfly valve a high-performance butterfly valve: the spindle offsets the center of the seal face to form the first eccentric, and the spindle offsets from the centerline of the pipeline to form the second eccentric. The eccentric lug butterfly valve will generate cam effect as the disc screw in or out, making it possible to separate the disc from seat by very small torque. In this way, there’s almost no friction between the disc and seat during switches and the service life is extended.

Specifications

We provide eccentric lug butterfly valves in a wide range of sizes. The main products are the following:

We also offer other sizes according to your demand.

Applications:

As we mentioned before, the lug-type butterfly valve is characterized by a unique connection design allowing the installation or removal of any side of the piping system without the need to shut down the entire system. For this reason, the butterfly lug type valve can even be used where the valve is at the end of a pipe.

Besides, the double offset design contributes to a better sealing effect of the eccentric lug butterfly valve. For this reason, this lug type butterfly valve is used for the applications:

Cooling water, air, gases, fire protection, etc.

Slurry and similar services

Vacuum service

High-pressure and high-temperature water and steam services

Compressed Air or Gas Applications.