Products

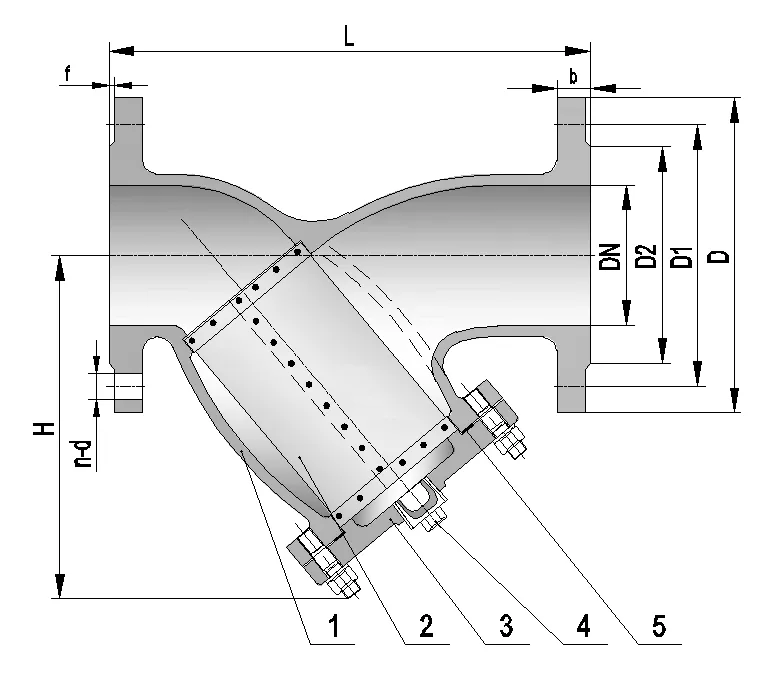

Y Type Flange End Strainer with Drain Cap

Flange dimensions Conform to EN1092-2 PN16/PN25

Testing Conform to EN12266-1

note:

1.DN50~DN300 meshes Φ1.5

DN350~DN600 meshes Φ3.0

2.It can be manufactured according to customer's requirement

3.DN450~DN600 Body and bonnet's materials are EN-GJS-450-10

Product Details

The whole is equipped with a drain plug in the lower part, which allows easy disassembly during the removal of contamination in the pipeline.

The position of the filter allows capturing contamination during unrestricted flow of the medium.

The strainer insert chamber is fitted with a cast iron cover sealed with a rubber sealing O-ring or graphite on a steel ring and bolted to the body using hex.

| Body | Ductile Iron |

| Cover | Ductile Iron |

| Mesh insert | Stainless steel PN-EN 10088-1:2014 |

| Seal | Graphite CrNiSt |

| Screw | PN-EN ISO 4016:2011 |

| Drain plug | Malleable Ductile Iron |

Application:

Operating temp. up +120°C, 70°C for EPDM.

Cast iron flange strainer is for drinking and technological water systems.

It is recommended to install the strainer horizontally at the lowest point of the pipeline or at bending points.

In order to ensure full operational functionality, it is recommended to rinse the strainers with clean water periodically (twice per year) or more frequently, depending on the medium contamination level.

| No. | Part Name | Material |

| 1 | BODY | EN-GJL-250/EN-GJS-450-10 |

| 2 | SCREEN | SS304 |

| 3 | BONNET | EN-GJL-250/EN-GJS-450-10 |

| 4 | PLUG | MALLEABLE CAST IRON |

| 5 | BONNET GASKET | Graphite +08F |

Dimension:

| DN | / | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | / | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 | 1100 | 1200 | 1250 | 1450 |

| D1 | / | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 |

| D2 | / | 99 | 118 | 132 | 156 | 184 | 211 | 266 | 319 | 370 | 429 | 480 | 548 | 609 | 720 |

| D | EN1092-2 | 165 | 185 | 200 | 220 | 250 | 285 | 340 | 405 | 460 | 520 | 580 | 640 | 715 | 840 |

| b | PN16 | 20 | 20 | 22 | 24 | 26 | 26 | 30 | 32 | 32 | 36 | 38 | 30 | 31.5 | 36 |

| n-d | / | 4-19 | 4-19 | 8-19 | 8-19 | 8-19 | 8-23 | 12-23 | 12-28 | 12-28 | 16-28 | 16-31 | 20-31 | 20-34 | 20-37 |

| D | EN1092-2 | 165 | 185 | 200 | 235 | 270 | 300 | 360 | 425 | 485 | 555 | 620 | 670 | 730 | 845 |

| b | PN25 | 19 | 19 | 19 | 19 | 19 | 20 | 22 | 24.5 | 27.5 | 30 | 32 | 34.5 | 36.5 | 42 |

| n-d | / | 4-19 | 8-19 | 8-19 | 8-23 | 8-28 | 8-28 | 12-28 | 12-31 | 16-31 | 16-34 | 16-37 | 20-37 | 20-37 | 20-41 |

| f | / | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 5 |

| H | / | 152 | 186.5 | 203 | 250 | 288 | 325 | 405 | 496 | 574 | 660 | 727 | 826.5 | 884 | 1022 |