Dimensional inspection and Seal test of cast iron valves

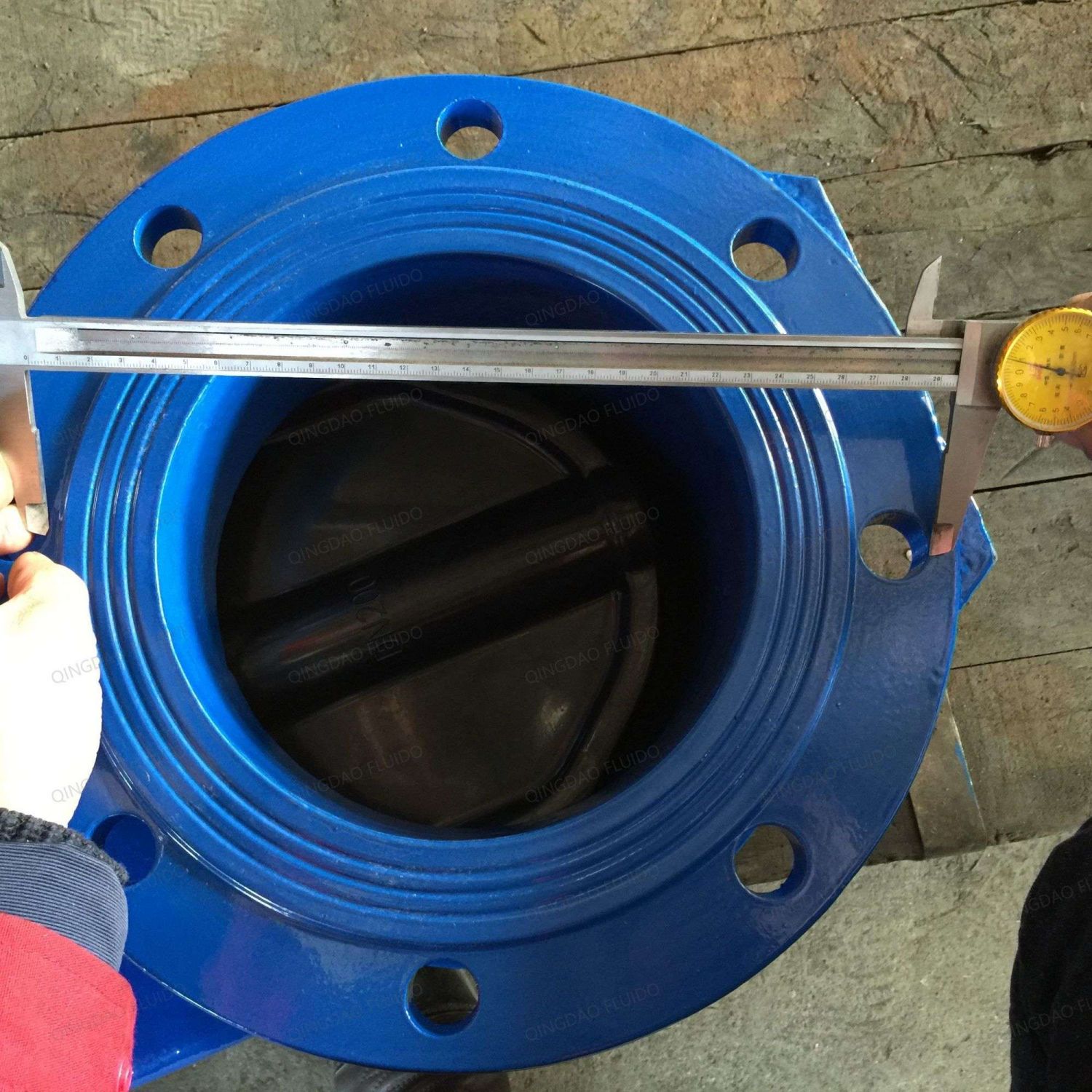

Dimensional inspection:

Valve dimensional inspection involves checking the dimensions and tolerances of various components to ensure they meet the required specifications. The following dimensions are usually checked:

1. Valve Body: Measure the overall length, width and height of the valve body to ensure that it meets the design requirements. In addition, check the inside and outside diameters of the valve body ports to ensure proper installation with other flanges, and joint fittings.

2. Bonnet and stem: Check the bonnet and stem lengths and diameters to ensure they are firmly installed and allow the valve to operate smoothly.

3. Flanges: Take measurements of the valve flanges, including diameter, bolt hole spacing, and thickness, to ensure correct alignment and connection to the piping.

4. Flaps and Seats: Check the valve flap and seat dimensions, such as diameter, thickness, and clearance, to ensure adequate sealing and flow control.

Seal test:

Seal tests are performed after the valve has been fully assembled and are essential to ensure that the valve will prevent leakage and maintain a reliable flow control system. The following sealing tests are usually performed, valves such as no special requirements are generally used pneumatic testing methods:

1. Hydrostatic test: the valve is filled with water or other suitable liquid and subjected to a specified pressure to check for any leakage. Any sign of leakage indicates that the valve is leaking. This is accomplished by filling the valve with water and gradually increasing the pressure.

2. Air Pressure Test: In this test, the valve is inflated by means of a device and its sealing performance is assessed by observing whether there is any leakage on the other side. Any leakage observed indicates a potential problem with the sealing ability of the valve.

Conclusion:

Dimensional inspection and seal testing are critical steps in ensuring the quality and performance of cast iron valves. After these inspections and tests, we can ensure that the valve meets the order requirements, these quality control measures can contribute to the overall reliability and service life of cast iron valves, if you have any other questions about cast iron valve testing, we welcome your contact at Fluido email: info@eathu.com.