The growing popularity of ductile iron A536 in valve manufacturing

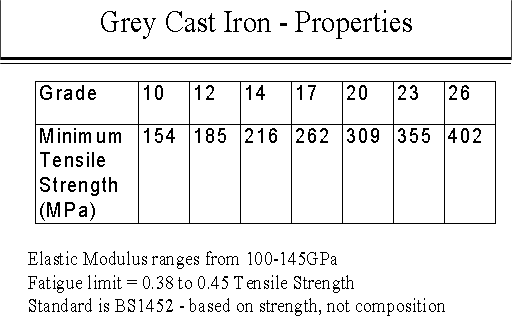

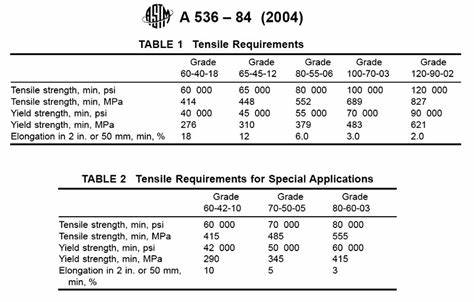

In cast iron valve material application, we use gray iron A126 as the preferred material for valve body and bonnet in the past. However, in recent years, there has been a growing acceptance and preference for ductile iron A536, also known as ductile iron or ductile cast iron. We will explain the reasons and compare the physical properties and chemical elements of the two materials.

1. superior mechanical properties:

Ductile Iron A536 has superior mechanical properties than Gray Iron A126, making it an ideal material for valve bodies and bonnets. Its high tensile strength, ductility and impact resistance make it highly reliable even under harsh conditions.

2. Enhanced corrosion resistance:

The one factor that determines the life of a valve is corrosion resistance. Gray cast iron A126, although widely used in the past, is relatively susceptible to corrosion. In contrast, ductile iron A536 has superior internal and external corrosion resistance. This characteristic significantly extends the service life of the valve, reduces maintenance costs and ensures operational efficiency.

3. Improved design flexibility:

Ductile iron A536 offers greater design flexibility than gray iron A126. Its superior machinability allows for complex designs and intricate geometries, enabling manufacturers to create valves that meet specific requirements. This sort of versatility is critical in industries where valves must be customized to fit unique applications.

4. Cost-effective solutions:

The growing acceptance of ductile iron A536 can also be attributed to its cost-effectiveness. While initially, the material may seem more expensive than gray iron A126, its durability and corrosion resistance can result in long-term cost savings. Valves made from ductile iron A536 offer a higher return on investment over their lifetime due to reduced maintenance and replacement requirements.

5. Environmental Factors:

Compared to gray cast iron A126, ductile iron A536 is considered a more environmentally friendly option because of its lower carbon footprint. Ductile iron is preferred by environmentally friendly customers because the production process uses less energy and emits fewer greenhouse gases.

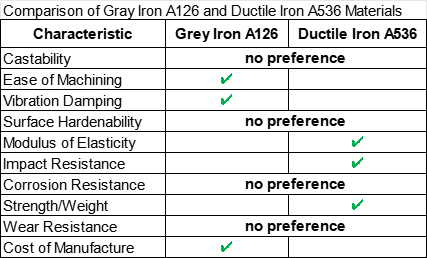

A material comparison table between valve gray iron A126 and ductile iron A536 is shown below:

Conclusion:

The growing popularity of ductile iron A536 in valve manufacturing can be attributed to its superior mechanical properties, enhanced corrosion resistance, improved design flexibility, cost-effectiveness and environmental sustainability. It is expected to become the standard choice for valve bodies and bonnets, replacing traditional grey iron A126, as more and more customers recognize the long-term benefits offered by this material.