The Distinction Between Cast Iron Valves, Cast Steel Valves and Forged Steel Valves

Manufacturing process:

Casting: Melt the shape memory alloy and fill the concave mold for cooling. Heat the metal material and pour it into the sand mold or mold shell, and solidify it into the equipment after cooling.

Forging: Mainly high-temperature extrusion processing. Through hammering and other methods, the metal material in the plastic state is transformed into a product workpiece with a certain shape and size, and its physical properties are changed.

1. Material: Cast iron valves are cast with gray cast iron, ductile iron and other materials.

2. The price of cast iron valves is relatively low, but its pressure and temperature resistance are limited, and it is prone to leakage and cracks and other problems.

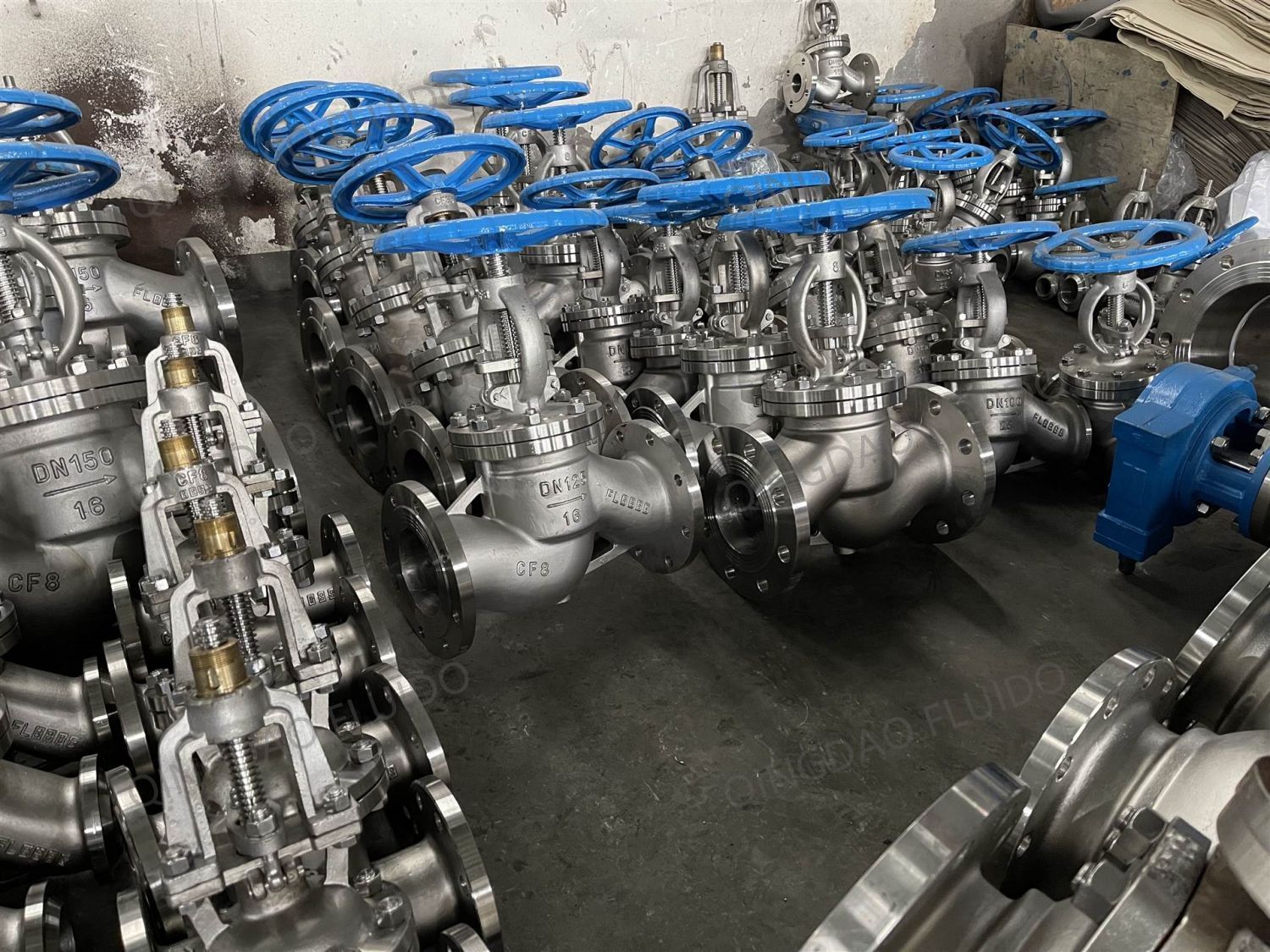

1. Material: Cast steel valves are generally cast with carbon steel, alloy steel and other materials.

2. Performance: Cast steel valves have better sealing performance when used and can withstand higher pressure and temperature, but the price is also higher

3. Usage scenarios

Since cast steel valves have high strength and corrosion resistance, they are often used in high-pressure and high-temperature pipelines in chemical, petroleum and other fields.

1. Material properties: Forged steel valves have good toughness and impact resistance.

2. Usage scenarios

Forged steel valves are suitable for high temperature, high pressure and large diameter valves.

3. Appearance

Cast steel valves and forged steel valves are very easy to distinguish in appearance design. Generally, cast steel valves are silver-white, while forged steel valves are black-gray.

QingDao FLUIDO is a valve corporation, we offer various types of cast valves and forged valves. If you have any needs, please feel free to contact us.